气动设计部分

Pneumatic Design Section

德耐尔离心压缩机的气动设计应用先进的空气动力学原理,并结合自主研发的高效建模软件、CFD 仿真等手段,确保了*优的级间压缩比分配及稳定可靠性,同时结合德耐尔技术开发团队长期产品验证的设计经验、丰富的叶轮数据库和设计软件,保证了气动设计的优越性。

The aerodynamic desien ot Dene centritugal compressor uses a dvanced aerodynamic princ ples, comb ined wit h self-develo ped eficient modeling software, CFD simulation and other means to ensure the optimal interstage compression ratio allocation and stability reliability, At the same time, combined with the long-term product verific ation design experience ofthe techn ical development team of Denier, rich im peller da tabase and design software, to ensure the superiority of pneumatic design.

叶轮强度分析

Impeller Strength Analysis

运用有限元分析软件,模拟叶轮在设计工况下的应力和变形量情况。应力分析结果为校核叶轮强度提供了科学的依据,防止机组在实际运行时因叶轮局部应力集中、强度不够酿成事故;计算的轴向、径向变形量为叶轮与进气缸间隙的取值提供了参考,防止机组运行时叶轮与进气缸发生相互刮擦,导致叶轮损毁等重大故障的发生。

The finite element analysis software is used to simulate the stress and deformation of the impeller under the desigr conditions. The results of stress analysis provide a scientific basis for checking the strength of the impeller, prevent accidents due to local stress concentration and insufficjent strength ofthe impeller during the actual operation ofthe unit; The calculated axial and radial deformations are the values of the gap between the impeller and the inlet cylinder. lt provides a reference to prevent the impeller and the intake cylinder from scraping each other when the unit is running, resulting in impellerdamage and other major failures.

转子动力设计

ROTOR DYNAMICS DESIGN

专 业设计的转子与轴承,确保能在合理的油膜温度、压力、厚度下运行,有效减少轴承功率消耗。提取大量轴承的刚度和阻尼数据,进行转子动力学分析,保证转子合理的振动值,确保额定转速设定远离临界转速运行,增强整机的稳定性。

Professionally designed rotors and bearings ensure that they can operate under reasonable oil film temperature, pressure and thickness, effectively reducing, bearing power consumption. Extract the stiffness and damping data of a large number of bearings, conduct rotor dynamics analysis, ensure a reasonable vibration value of the rotor, also ensure that the rated speed setting is far away from the critical speed and enhance the stability of the whole machine.

高可靠性轴承

High Reliability Bearing

精心设计 稳定可靠

Exguisite design Stability and Reliability

通过转子动力学

专 业设计,采用负载能力强、振动低的可倾瓦轴承。轴承轴瓦可根据负荷与温度变化自动调心,保证机组在应对多种恶劣工况时能够稳定运行。

Through the professional design of rotor dynamics, the tilting pad bearing with high load capacity and low vibration is adopted. The bearing bush can be automatically adjusted according to the load and temperature changes, so as to ensure the stable operation of the unit undervarious harsh working conditions

整体铸件齿轮箱-模块化集成装配

Integral casting gearbox-Modularintegrated assembly

水平剖分式齿轮箱与各级蜗壳一体铸造,冷却器箱体整体铸造,模块化设计。与焊接齿轮箱分体式结构相比,主机机构强度更高、加工面更少、运行更可靠,各级蜗壳与齿轮箱体无装配误差、无变形、噪音低、振动小。与整体铸造相比,加工、装配、运输、现场安装、维护更加简便,在主机需要返厂大修的情况下,整体铸件需要更大起吊设备且破坏安装基础导致二次安装,而模块化的设计则完美解决这一问题。

The horizontally split gearbox is integrally cast with the volutes at all stages, and the cooler box is integralh cast with a modular design. Compared with the split structure of the welded gearbox, the main engine mechanism has higher strength, fewer processing surfaces, and more reliable operation. There is no assembly error, no deformation, low noise and low vibration between the volute and the gear box at all stages. Compared with integral casting, processing, assembly, transportation, on-site installation and maintenance are simpler. When the main engine needs to be returned to the factory for overhaul, the integral casting requires larger lifting equipment and destroys the installation foundation. resulting in secondaryinstallation, The modular desien it pertectily solves this problem.

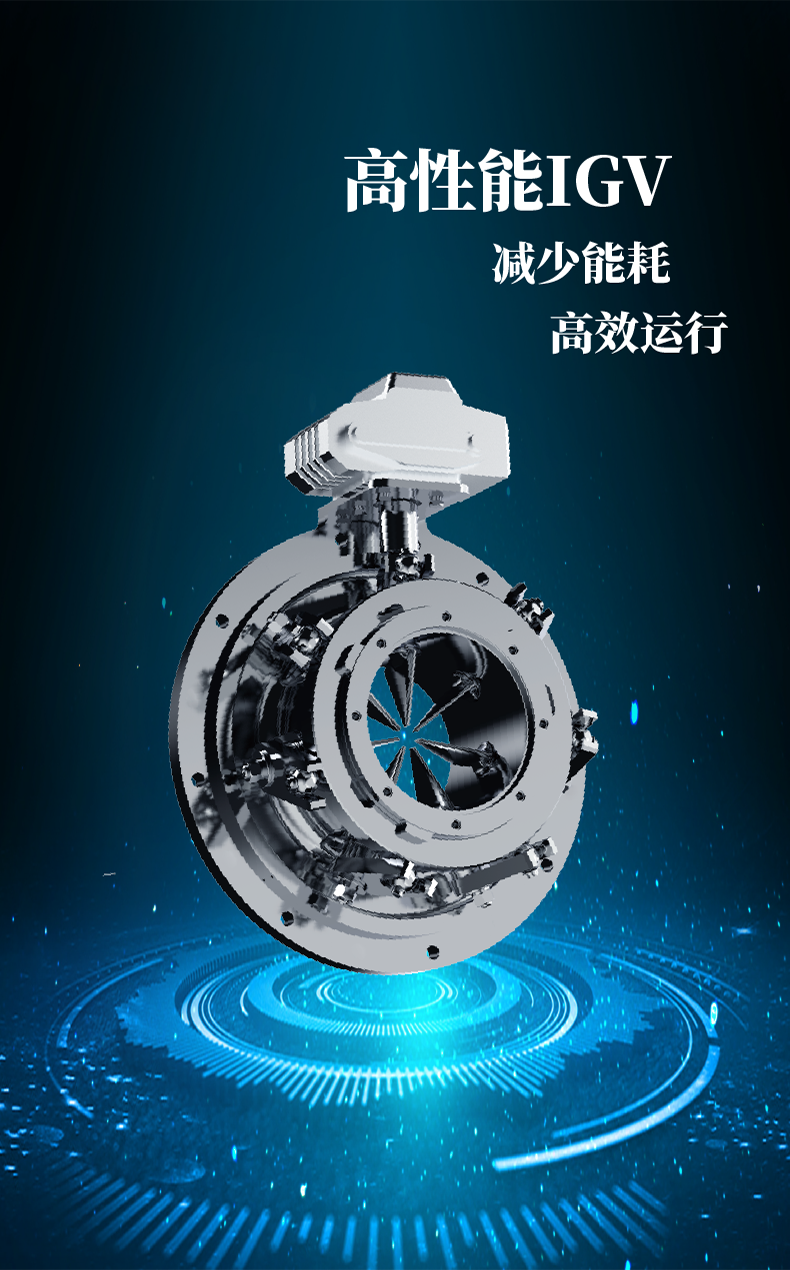

高性能IGV

High Performance lGV

逸 电动执行器驱动翼型不锈钢叶片,对进口导叶开度进行精确控制,改变进气的预旋值,提高离心压缩机运行效率,在压缩空气需求量减少时 IGV可节省*高约 9% 的能耗,使离心压缩机

高 效 节 能运行。

The electric actuator drives the airfoil stainless steel blades, precisely controls the opening of the inlet guide vanes. changes the pre-swirl value of the intake air, and improves the operating efficiency ofthe centrifugal compressor. When the compressed airdemand is reduced. the IGV can save up to about 9%.Energy consumption,making the centrifugal compressor run efficiently and energy-saving.

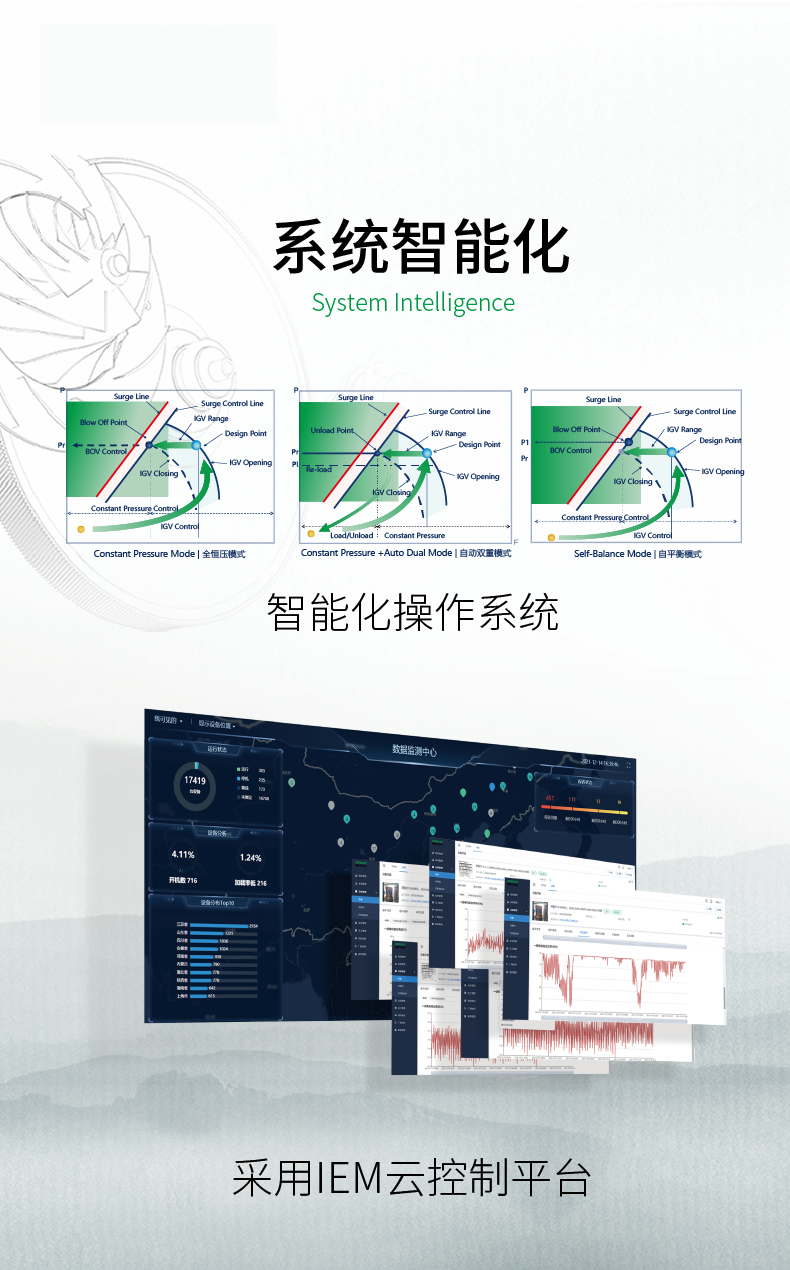

智能化控制系统

Intelligent control system

德耐尔DAC系列离心式压缩机控制系统可以实现全恒压模式、自动双重模式、自平衡模式三种运行模式。能根据客户实际运行工况变化及气量需求进行智能调节,确保设备始终处于

高 效 节 能稳定运行状态。

Denair DAC series centrifugal compressor control system can realize three operating modes: full constant pressure mode, automatic dual mode and self-balancing mode. lt can intelligently adjust accord ing to the actual operation conditions and gas demand of customers to ensure that the equipment is always in a state of high efficiency, energy saving and stable operation.

采用IEM云控制平台,可对用户空压系统所有设备运行数据的实时采集,并利用AI,云计算先进技术对数据进行跟踪及分析优化,实现客户站房系统的智能化、可视化。

Using the lEM cloud control platform, it can collect real-time operation data of all equipment in the user’s air compressor system, and use Al and advanced cloud computing technologies to track, analvze and optimize the data to realizethe intelligence and visualization ofthe customer station system.

控制柜 Control cabinet

高度集成的机组控制系统,采用西门子PLC及触摸显示屏,控制界面简洁明了,触摸操作简单方便。操作界面支持多种语言切换,显示屏可以实时监控机组内所有参数,将各级关键运行参数实时以运行曲线与数字的方式呈现,自动报警及连锁停机保护,同时具备防喘振和喘振预测功能,确保设备运行的安全和可靠性。

The highly integrated unit control system adopts Siemens PLC and touch display screen, the control interface is concise and clear and the touch operation is simple and convenient.The operation interface supports multi-language switching and the display screen can monitor all parameters in the unit in real time, present key operating parameters at all levels in real time in the form ofrunning curves and numbers, automatic alarm and chain shutdown protection and anti-surge and surge prediction function to ensure the safety and reliabilityofeq uipment operation.

扫一扫,手机浏览

扫一扫,手机浏览