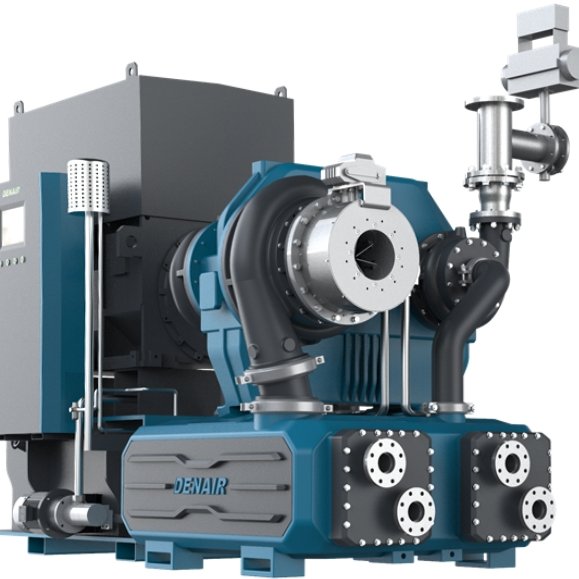

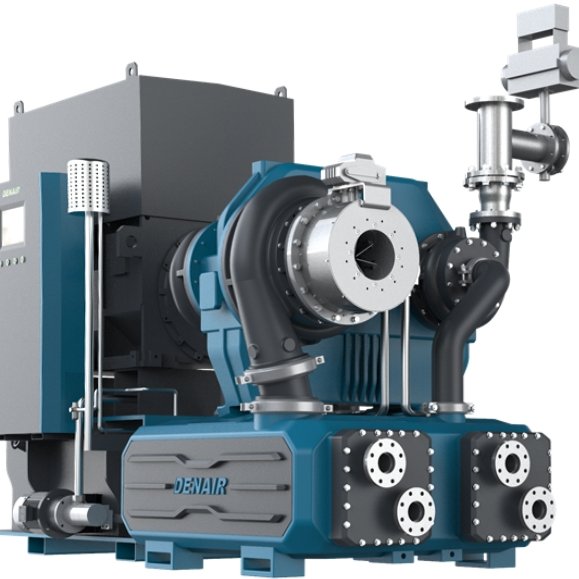

离心式压缩机

CENTRIFUGE COMPRESSOR

气动设计部分

Pneumatic Design Section

德耐尔离心压缩机的气动设计应用先进的空气动力学原理,并结合自主研发的高效建模软件、CFD 仿真等手段,确保了*优的级间压缩比分配及稳定可靠性,同时结合德耐尔技术开发团队长期产品验证的设计经验、丰富的叶轮数据库和设计软件,保证了气动设计的优越性。

The aerodynamic desien ot Dene centritugal compressor uses a dvanced aerodynamic princ ples, comb ined wit h self-develo ped eficient modeling software, CFD simulation and other means to ensure the optimal interstage compression ratio allocation and stability reliability, At the same time, combined with the long-term product verific ation design experience ofthe techn ical development team of Denier, rich im peller da tabase and design software, to ensure the superiority of pneumatic design.

叶轮强度分析

Impeller Strength Analysis

运用有限元分析软件,模拟叶轮在设计工况下的应力和变形量情况。应力分析结果为校核叶轮强度提供了科学的依据,防止机组在实际运行时因叶轮局部应力集中、强度不够酿成事故;计算的轴向、径向变形量为叶轮与进气缸间隙的取值提供了参考,防止机组运行时叶轮与进气缸发生相互刮擦,导致叶轮损毁等重大故障的发生。

The finite element analysis software is used to simulate the stress and deformation of the impeller under the desigr conditions. The results of stress analysis provide a scientific basis for checking the strength of the impeller, prevent accidents due to local stress concentration and insufficjent strength ofthe impeller during the actual operation ofthe unit; The calculated axial and radial deformations are the values of the gap between the impeller and the inlet cylinder. lt provides a reference to prevent the impeller and the intake cylinder from scraping each other when the unit is running, resulting in impellerdamage and other major failures.

转子动力设计

ROTOR DYNAMICS DESIGN

专 业设计的转子与轴承,确保能在合理的油膜温度、压力、厚度下运行,有效减少轴承功率消耗。提取大量轴承的刚度和阻尼数据,进行转子动力学分析,保证转子合理的振动值,确保额定转速设定远离临界转速运行,增强整机的稳定性。

Professionally designed rotors and bearings ensure that they can operate under reasonable oil film temperature, pressure and thickness, effectively reducing, bearing power consumption. Extract the stiffness and damping data of a large number of bearings, conduct rotor dynamics analysis, ensure a reasonable vibration value of the rotor, also ensure that the rated speed setting is far away from the critical speed and enhance the stability of the whole machine.

扫一扫,手机浏览

扫一扫,手机浏览