无油涡旋空压机(2.2~37kw)

OIL-FREE SCROLLAIR COMPRESSOR(2.2~37KW)

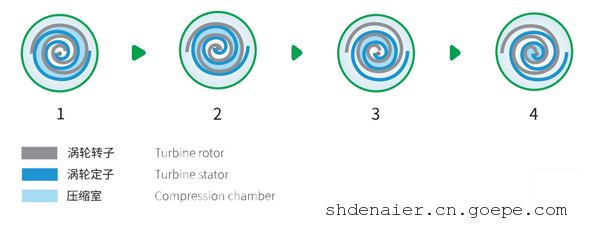

无油涡旋空压机原理

Oil-free Scroll Compressor Principle

涡轮转子按图 1→2→3→4 的顺序旋转,空气被吸至涡轮定子与涡轮转子之间的空间,呈月牙形(成点对称状) 的压缩室容积逐渐变小,空气经压缩后从中心部位的排气口排出。

The turbine rotor rotates in the order shown in Fig, 1 - 2 - 3 -> 4, The air is drawn into the space between the turbine stator andthe turbine rotor The volume ofthe crescent shaped looint symmetrical compression chamber gradually decreases, and the air iscompressed and discharged from the exhaust port at the center.

无油涡旋空压机适用行业

Oil-free Scroll Compressor

无油涡旋空压机生产不含油的高质纯净压缩空气,广泛应用于食品饮料、生物医药、电子半导体、科学实验室、化工及精密喷涂等领域。

The oilfree scroll air compressor produces oi-free high-quality pure compressed air, which is widely used in food and beveragebiological medicine, electronic semiconductor, scientific laboratory, chemical industry, precision spraying and other fields.

安静 Quiet

涡旋式压缩机静音、微振动,提供舒适的作业空间,即使夜间运转也无需担心影响环境。The scroll compressor is quiet and slightly vibrated, providing a comfor-table workingspace,There is no need to worry about the impact on the environment even if it operates at night.

节能 Saving

将多台空压机内置于1台机箱中,通过多级控制实现运转和节能。根据使用空气量,采用通过台数进行自由运转的多级控制,从而免除了不必要运转,实现了节能。

Several air compressors are built into one cabinet to realize operationand energy saving through multi-level control. According to theamount of air used, multi-level control of free operation through thenumber of units is adopted, thus eliminating unnecessary operationand realizing energy conservation.

扫一扫,手机浏览

扫一扫,手机浏览